IN MEMORIAM WILLIAM ANDERS

Bill Anders lost his life in a tragic accident ending an exemplary career as an aviator an astronaut and a revered and loved husband and father.

As he did frequently, Bill took his T-34 ex-military trainer for a routine flight in the beautiful skies over the San Juan Islands in Washington State.

A video taken shows a meticulously flown flight path that he had flown countless times before around homes of friends he cared about so deeply.

But Bill was 90 years of age and although healthy enough to fly, flying is a jealous mistress and if something goes wrong, whether it’s the airplane or the pilot, even for the most skilled, the outcome can be unpredictable.

As soon as the small piece of video of the last seconds of the flight was published, speculation on social media was rampant that Bill misjudged the bottom of a loop and crashed or he was not paying attention because his glasses fell off or he dropped his phone. Anyone who knew him and knew his discipline as a pilot would know that he would never allow something like that to happen and while it’s exciting to look at, a loop is one of the easiest of all aviation maneuvers to accomplish safely.

A look at the entire video reveals instead that about 8 seconds before the crash, it appears that something went terribly wrong. The airplane instead of completing a turn, all of a sudden went vertical in descent and in the last few seconds it appears an effort was made to recover which was too little too late.

Reconstructing aircraft accidents has been my life’s work and flying aerobatics in airshows was a past life.

This accident is a classic case of momentary incapacitation resulting in a loss of control and when consciousness was regained a recovery was initiated that was too late. This same kind of accident has occurred countless times in the past whether in a military aircraft duringACM or a civilian aircraft while performing maneuvers that pull G’s regardless of youth or physical condition.

Bill Anders was an awesome man who is honored for his unique contribution to aviation and remarkable aerospace achievements. He will be remembered fondly, lovingly and respectfully by all who knew him.

What better tribute for a man!

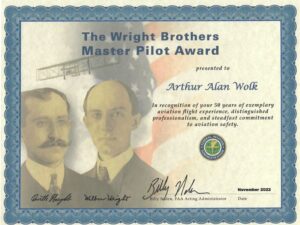

Arthur Alan Wolk

June 12, 2024

Photography by NASA & CelebJam